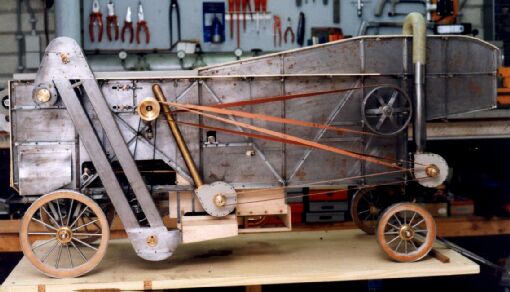

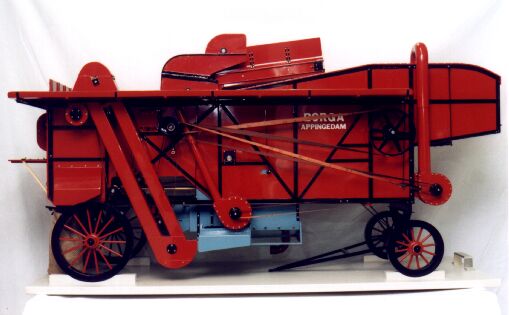

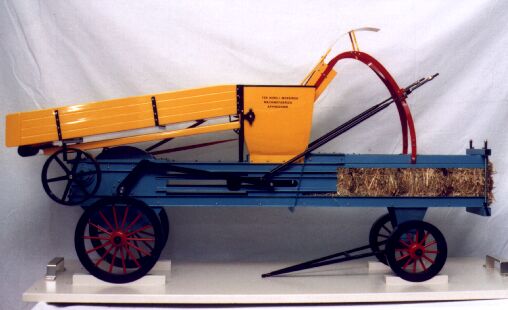

During the 1930s large threshing machines, for example produce of Borga or Lanz, came in use. The Borga threshing machine is build by "Borg en Mensingsa"-engineering works in Appingedam. Nowadays these big machines are out of use and displaced by combines. Fortunately in the Netherlands some enthusiasts saved several of these machines from the scrapheap and restorated them to be as good as new. The photograph alongside is taken at harvest home in Kamperland. This machine and baler are restorated with devotion and patience of Job by L.P. Brasser, farmer from St. Laurens.